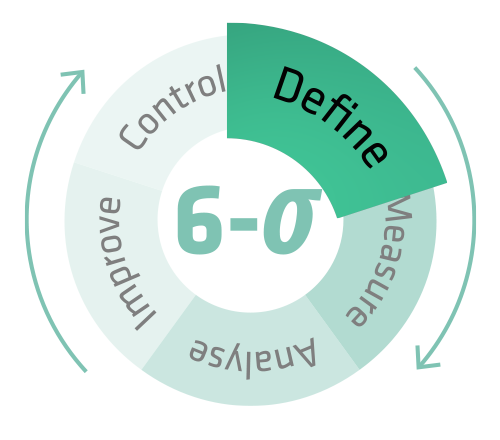

The Six Sigma method

The “DMAIC-Cycle“ is ideally used as standard operating procedure for running Six Sigma projects.This project- and control circuit is used for statistical data analysis of causal relationships in regards to “cause and effect” at already existing processes in order to reach the demanded target level.

Define phase (visit in your company):

Serves the purpose to clearly identify the measurable problem.

- mapping of a measurable problem and determination of the resources (e.g. measurement data, which must be collected if needed)

- specification of the time period to be analysed and the measurement frequency in relation to the objective

- distribution of the tasks

- consideration of specific process changes (e.g. conversions), which are not included in the data

Measuring phase:

How well does the existing process meet the demands?

- generating and providing measurement data (your task)

- visualisation of the dimension of the problem

- evaluation of the data quality

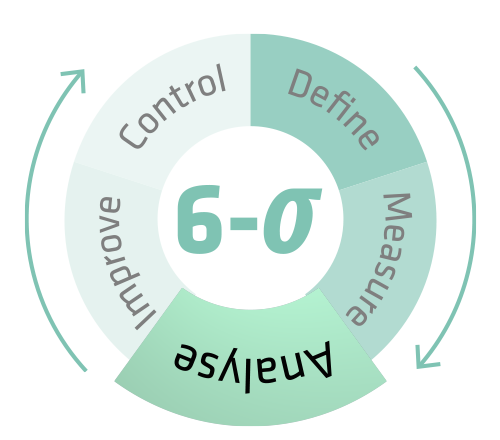

Analysis phase (followed by the presentation of the results):

In this phase, the actual statistical data analysis takes place in order to investigate the “cause-effect” relations and to identify the main reasons for the problem.

- illustration of the current process, identification of the main causes

- display and evaluation of the effects of the raw materials and auxiliaries as well as paper machine clothing

- generating new key performance indicators (KPI´s) for subsequent relief of the process control

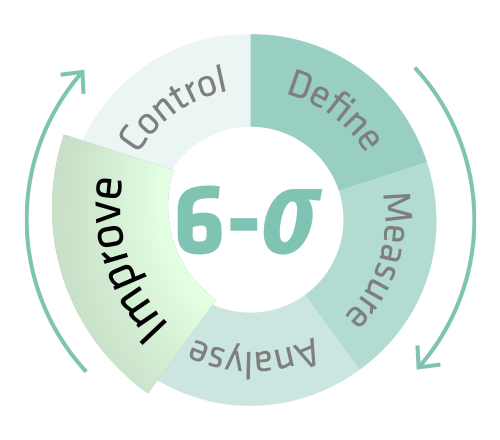

Improve phase:

Potential process improvements are planned, tested and introduced.

- if necessary the determined influencing variables can be confirmed with the help of statistically designed trials (Design Of Experiments – DOE)

- selection of the best solution

- implementation plans are developed by yourself

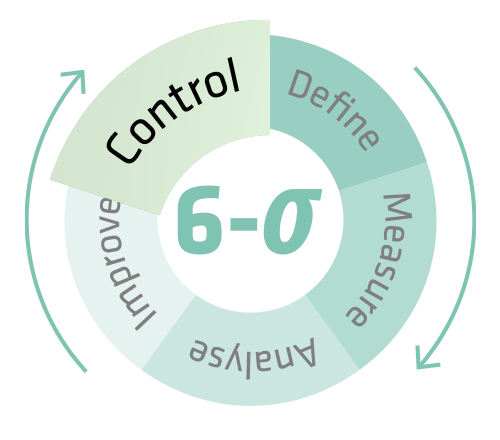

Control phase (your task):

Process monitoring using appropriate methods in order to ensure a sustainable process improvement.

- documentation of the new improved processes

- staff training

- selection, registration and securing of the key performance indicators

- saving of the graphical controls of these variables