Statistical Process Optimisation

You can most likely find the key to optimise your process in your database!

The paper production process is characterized by a high number of potentially significant influencing factors. Measures for a sustainable process optimisation can only be carried out by knowing the real significance of the key performance input variables and their relations to each other. In addition to that, the paper industry has also not been spared from very high personnel reductions. The resources to carry out sustainable process optimisation measures are scarce. Therefore, the paper industry needs economically useful and measurable process optimisation methods. With my expert knowledge and experience I can assist you with these challenges!

Statistical Process Optimisation Services

Reducing costs, improving quality

Reduce your broke!

Causes for process faults and paper breaks can be found with the help of statistical data analysis, even if these can be traced back to paper quality properties.

Your processes can be specifically targeted and controlled by the Statistical Process Optimisation.

Increase your productivity

Increase your paper production by stabilising the paper machine runnability!

The key performance input variables are determined with the help of statistical process data analysis. Consequently, the reasons for any performance variations can be analysed. This facilitates the steering and control of the process and consequently leads to more stable processes.

Process variations are specifically reduced in paper production.

Improve the product quality

Impress your customers with consistently good paper quality and custom-made quality criteria!

The main factors and with it the causes for variations of the different paper quality parameters are analysed. My knowledge in statistical process data analysis allows a reduction of the variations of the paper quality. This opens up new possibilities for you to purposefully adjust and control the paper quality.

This opens you new ground, adjusting and controlling the paper quality purposefully.

Save your valuable working time

Statistically significant improvement of your paper manufacturing process will cut down your working hours and save resources within the shortest time!

You supply your experience and the historical process data – I add the results of my statistical data analysis. Together we evaluate and interpret the results and subsequently optimise your process. You broaden your process knowledge with a minimum of your own human resources. It simplifies the steering and control of the production process and significantly saves expenses for your own human resources.

This simplifies the steering and the control of the production process and saves your human resources significantly.

Prepare yourself for the future

Establish the basis to achieve Process Excellence!

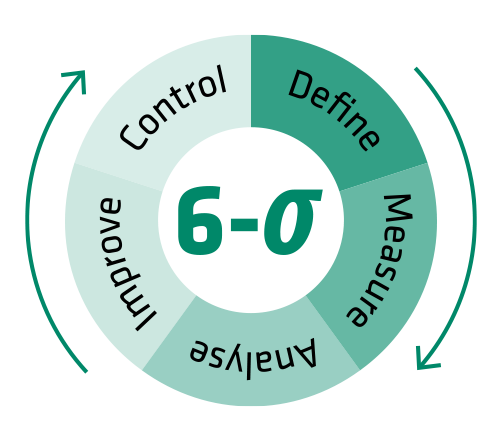

Benefit from the advantages of the in-house statistical process data analysis.The use of the statistical data analysis is much more efficient and effective because of the improvement of the process capability and the reduction of the results’ variances due to the “jump-effect”, a perfect combination of improvement projects and continuous improvement processes. Whether you require single modules or complete belt trainings, I offer consulting, training sessions and coaching based on your individual needs and demands.

This opens new ways for you to improve your competitiveness.

My name is Konrad Höglauer. I worked for 6 years as a sales engineer for paper chemicals at Rhône-Poulenc GmbH in Frankfurt am Main. Beginning of 1996 I started with Albany International in Goeppingen/Ahlen. I was in charge of selling Paper Machine Clothing and was promoted to Sales- and Production Manager beginning of 1997. Starting in 2008 I was working on the development of a concept to use statistical process data analysis as a service tool for the paper industry in Europe and Asia. I carried out statistical data analysis with key customers and trained colleagues to purposefully use these tools. Overcoming multiple challenges in the Statistical Process Optimisation in the paper industry, I was able to improve the method continuously and to extend the application. In May 2015, I founded SPO-Consulting with the objective to support you in optimising your processes.

The discovery of new and important process details which are hidden away in your database is a special challenge for me!

My offer includes:

- Statistical data analysis for Process Optimisation

- personal assistance and execution of statistically designed trials (Design Of Experiments – DOE)

- Customised (e.g. Six Sigma Belt-) Training, Consulting and Coaching on the subject of Statistical Process Optimisation

Contact

Konrad Höglauer SPO-Consulting

Seestraße 14

D-73099 Adelberg